Appropriate technology

Technologies and societies co-evolve.

The thinking behind the development of a technology has been made possible by a society's culture.. and... viceversa, a technology adopted by a society is able to deeply influence the way that society functions and thinks.

One of our founding principles is to be intentional on the technical means we use to satisfy our day-to-day needs. We strive for autonomy not only from a food production standpoint, but also for our materials supply (recuperate discarded materials and reuse them, repair old tools or try to self-build some), energy, sanitation, water...

The goal is to free ourselves more and more from our dependence on an industrial system that has a catastrophic impact on the environment and society.

The concept of appropriate technology has been developed in the last decades to denote technologies that are more human-centered, decentralized, small scale, right-sized, simple, resilient, ecological etc... In short, they are technologies that make sense from a purely logical standpoint! We believe these are the innovations which will thrive in a future where fossil fuels will be scarce.

Our approach is to build, test and evaluate each innovation by using it in real life. So here I will outline some our technologies and make some reflections about our overall user experience.

Outside (summer) cooking:

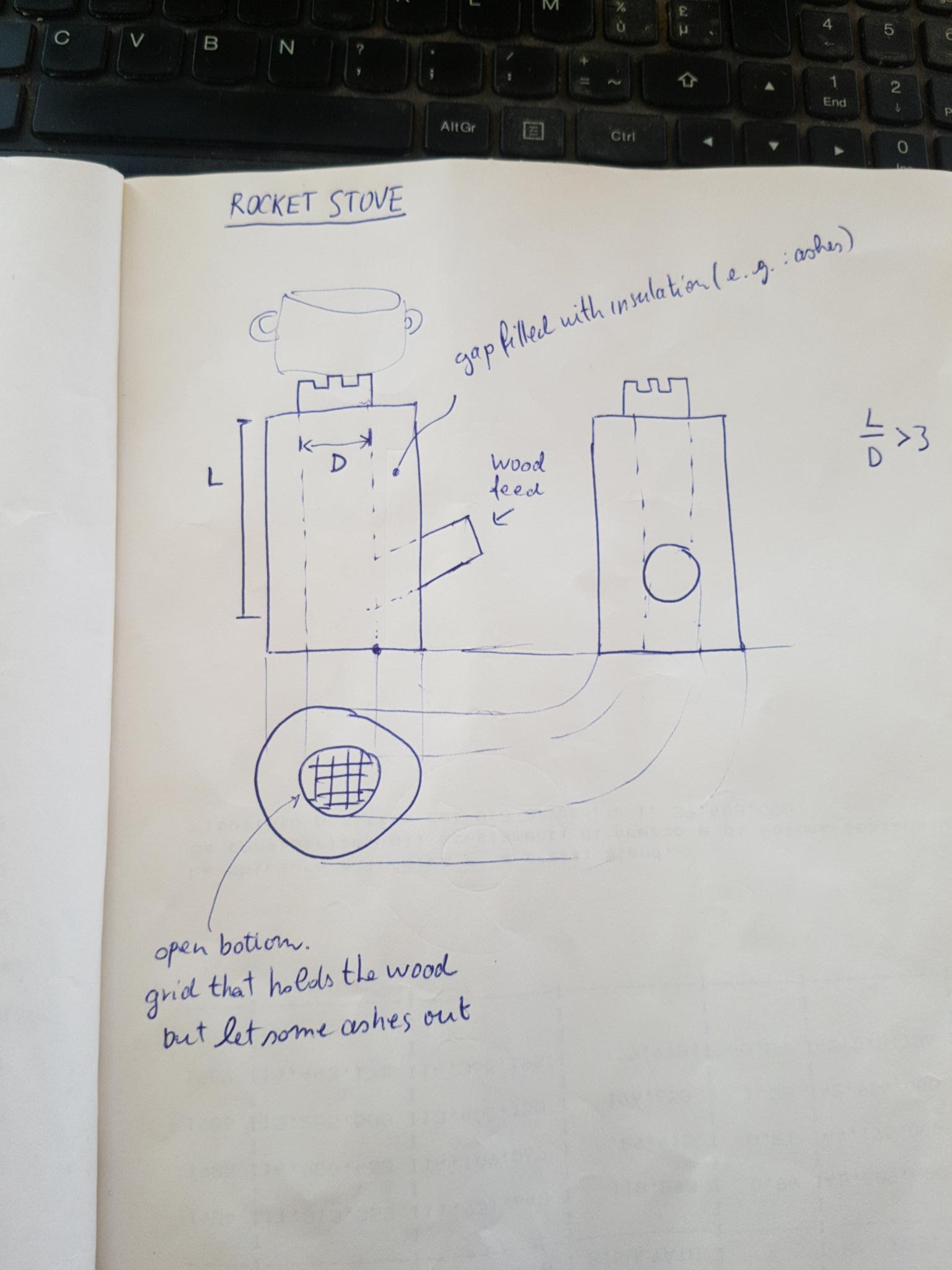

Rocket stoves

We fabricated our stoves from scrap metal using rudimentary tools. The design is an improvement of the Ecotopia's stoves

The rocket stove concept is simple: by using 2 concentric elements (an inner tube and an external barrel) and by filling the gap between them with ash (or sand or other material that blocks heat from escaping) you create an insulated chimney into which you make the fire. In this way, the heat from the fire is kept into the system and the upper part of the chimney reaches very high temperatures. This results in a post-combustion of the flu gases, leading to a very efficient burning of the firewood.

Sketch: Notice the design modifications vs the Ecotopia stoves

Sketch: Notice the design modifications vs the Ecotopia stoves

View from the top: notice the bottom grid and the connection with the feed channel on the side

View from the top: notice the bottom grid and the connection with the feed channel on the side

The top part of this stove has been repaired as the top part of the external drum was corroded

The top part of this stove has been repaired as the top part of the external drum was corroded

Our main innovation in the stove design is that the vertical channel goes all the way to the bottom of the external barrel and a grid is put at its exit. This helps having some extra air intake in the beginning of the fire (then it gets clogged with ashes) and also makes it easy to avoid accumulation of ashes.

Equally importantly, the inner chimney and the side feed tube are made of stainless steel in order to limit corrosion. A stainless steel sheet can be bent and formed into a pipe using simple handtools.

Cherry on the cake: the ergonomic positioning of the stoves! (a) on a washing machine drum, so that can be easily rotated to improve air intake, (b) on a metal support for flower vases. In both cases the ashes that form in the stove can fall down thru the grid and be evacuated.

We keep a supply of dry wood always readily available nearby. The stoves are useful to get rid of prunings, small wood cuttings, paper etc..

Evaluation: 5 stars

- The stoves are easily movable, so they can be removed and stored after use to allow freeing the space for other activities. in our case this allows use of the stoves near the house, close to the house kitchen.

- Being in metal they are prone to corrosion. For a more durable design it is better to build the stoves with mud and bricks, but this will require a dedicated space for them (external kitchen)

- Durability is greatly improved by using an inner pipe made of stainless steel (lifetime of years rather than months!). The external part of the stove still needs repairs from time to time. Don't leave the stoves outside under the rain!

- Startup of the stoves is very fast if using dry wood and paper. Efficiency of burning is very good. A few small pieces of scrap wood can go a long way!

- The main inconvenient is the blackening of the lower side of the pans. It is recommended to have dedicated pans for external cooking and never bring them inside a kitchen.

- A bit of attention is needed during cooking to avoid occasional ashes to fall into the meal. Always keep the lid closed when adding wood to the fire or during startup (smoky)

External kitchen setup. One stove is on a rotating drum the other one on a flower pot

External kitchen setup. One stove is on a rotating drum the other one on a flower pot

Rocket biochar stove

In theory, this this type of technology represents the "ultimate appropriateness" for a cooking device! At the same time as cooking your favorite dish you can produce biochar (to use as a soil amendment or a a filter). Moreover, the heat released during the biochar formation (pyrolisis) helps the cooking process so that minimal wood and minimal attendance during cooking is required.

Our design is again of the rocket-type, but in this case the bottom plate of the external barrel can be removed. At this point the stove can be turned upside down to fill the annular gap (where normally insulation is) with wood in small pieces. Then the stove can be closed again and reversed to start cooking by burning wood in the inner tube (as normal).

Biochar stove upside down: the bottom was opened and wood bark inserted in the gap

Biochar stove upside down: the bottom was opened and wood bark inserted in the gap

Biochar stove in upright position. The bottom is now closed; Ready to use!

Biochar stove in upright position. The bottom is now closed; Ready to use!

We are testing cooking times needed to obtain biochar starting from wood of different sizes and types. For small branches cut into pieces 80 minutes are sufficient to obtain good quality biochar.

But there are some warnings:

- due to the pyrolithic reaction in the annular gap (under high temperature and lack of oxigen, the wood in the gap undergoes a chemical transformation to biochar and tar and this reaction releases extra heat), the external surface of the stove reaches much higher temperatures than for a normal rocket stove

- pyrolitic gases escape during cooking from several points in the stove, therefore it is impractical to stand near the stove too much during cooking. Close the cooking pots with a lid to avoid gases getting into contact with the food. Best used for dishes that do not require constant stirring/checking/ attendance

Evaluation: 2 stars

Cool theory behind it and very elegant design, but.... a bit impractical for cooking due to release of lots of gases and tar oil from the bottom. More suited to heat up large pots of water to be used for food processing, rather than for cooking food itself!

After cooking our meal, at some point we notice that pyrolithic gases stop coming out.Some time after that, we get the biochar out and quench it using cold water. Photo: the biochar is ready!

After cooking our meal, at some point we notice that pyrolithic gases stop coming out.Some time after that, we get the biochar out and quench it using cold water. Photo: the biochar is ready!

Oven for the rocket stove

- We fitted an oven on top of a rocket stove

- Easily assembled and disassembled

- We used parts from 2 different ovens which were designed to fit on a gas kitchen : fornetto estense and fornetto recofix. They were both a legacy from my grandma. These 2 devices fit one into the other giving the increased insulation which is necessary for an homogeneous cooking on a rocket stove

- No flu gases/ smoke going into the oven and through the food (like in the case of oven going on top of kitchen gas)

- The tray with the food to be baked needs to sit on a spacer (upside down metal tray) to guarantee an homogeneous cooking

The oven in operation. It is necessary that no fumes can enter the cooking chamber

The oven in operation. It is necessary that no fumes can enter the cooking chamber

Evaluation: 2 stars

- Oven with a poor performance. If the fire is kept strong for about 1 hour the oven is able to cook a banana bread, but it requires checking and feeding wood about every 10 min. By putting alarm clocks on my watch I manage to follow the cooking and do something else at the same time

Inside (winter) cooking and heating:

"Putagé" wood stove

We bought second hand a small (5kW) stove with kitchen and oven.

To improve the performance of the oven we inserted one high temperature brick inside it (more thermal mass). This was a cheap (4.5 euros) and quick fix but stabilized oven's temperature considerably and now we use it once a week to bake bread.

Evaluation: 4 stars

The stove is not as quick as the rocket stoves to startup and consumes more and higher quality wood for operating it. However it performs decently for cooking and heating. (And sometimes it's nice to cook inside:) We installed some trays on top of it so that we can use it to keep stuff warm or as a dryer.

The "putagé" stove. Notice the small drying/heating rack installed above it

The "putagé" stove. Notice the small drying/heating rack installed above it

Washing

Pedal washing machine

We obtained a discarded washing machine and connected it to a pedal powered shaft to be able to move the drum.

The washing machine is fed with water from the top drawer. The day before washing we heat water on the putagé or on the rocket stove and we then store the water in a 30L thermos. Then we feed this water to the machine and add also more water at ambient temperature. Then there is one cycle of washing (with detergent) where we pedal back and forth for about 45 min (while reading a book), followed by draining and 2 cycles of rinsing with cold water (each cycle lasts 10 min).

Evaluation: 2 stars

Working with the washing machine is cumbersome and lengthy and the performance worse than that of an electric one. It is not possible to centrifuge well after washing. Overall is a good tool for demonstration and infrequent use, but as long as in the house an electric washing machine is present, I think we will end up mostly using that one. in summer it may be even better to just wash clothes by hand ...or by foot: you just put clothes in soapy water in a canister and then dance on them barefooted for a few minutes!

You take a chair , sit back and pedal...with a good book!

You take a chair , sit back and pedal...with a good book!

30 -40 L thermos to collect hot water to use in the washing machine

30 -40 L thermos to collect hot water to use in the washing machine

Sanitation

Dry toilets

We have plenty of compost toilets and we can satisfy you whether you are a "squatter" or a "sitter". There is a turkish-style toilet outside with a decent sunset view and two english-style WCs in the house.

When talking about dry toilet, we need to distinguish between the toilet itself (the very device receiving the droppings) and the "special waste" compost pile (where the droppings are transferred for long term disposal)

The toilet itself is as simple as the problem we are trying to solve, consisting in a single plastic bucket with a little of a frame around it and a lid to be able to close it.

- The user throws a handful of straw (or woodchips) on top of the faeces. Sawdust does not work as it smells and attracts maggots

- These are shitting-only toilets. For peeing, we tend to do it in nature, best if under heavey cropping fruit trees. However, when using the toilets, nobody is required strange acrobatics in order to separate pee and poo. If some pee goes into the bucket, even better!.. it helps sterilizing it with ammonia formation.

- So far I've not sanitized the buckets in 15 months and they still don't smell. Once you shit in them once, you can do that forever with no adverse side effects, basically!

- Not much smell even in summer and not many flies both in the toilets and in the "special waste" compost pile

The "special waste" compost pile is the real heart of the system and the more critical part, as it requires careful thinking to ensure the decomposition process happens efficiently and safely.

In our case we have an enclosed structure, protecting its contents from rain and animals. Once the structure is full it is moved somewhere else and the pile is buried under a thick layer of stray and wood chips to continue decomposing for another couple of years.

- Adding ashes and eldertree leaves in the compost pile deters flies

- Adding leaves, straw and other organic matter from the garden is essential to increase the Carbon-to-Nitrogen ratio

Evaluation: 5 stars

No one died yet :) Jokes aside, pooing in water is absurd and adopting a more logical solution makes me feel better. Concerning the design, it is very simple! I've travelled around and seen a lot of complicated designs: but never really understood their benefits. Often they present additional problems: difficulty in emptying them, inefficient composting process etc... But why, why, why.. complicating your life if the solution looks like the photo below?

Our first "historical" compost toilet

Our first "historical" compost toilet

External "turkish style" compost toilet

External "turkish style" compost toilet

The latest addition: a second dry toilet inside the house

The latest addition: a second dry toilet inside the house

Shit composting pile on the background. Old pile buried under woodchips on the foregrond

Shit composting pile on the background. Old pile buried under woodchips on the foregrond

House winter heating

- First and foremost heating system are warm clothes!

- A putagé to warm the downstairs kitchen

- Small old coal stove to warm the small upstais kitchen (converted to smart-working office)

- Possibility to warm (a bit) the rooms in the old house with a centralised stove that works with oats (or wood). We basically never use it.

- Possibility to warm an extra space in the new house (if needed) using air-con heat pump. To be limited, but good to do it for short periods when needed (i.e. to provide some thermal comfort to visiting guests)

Evaluation: 3 stars

The putagé stove struggles to heat our big common room in the coldest months. We will need improved solutions in place before next winter. Wood consumption this year has been quite low, less than a third of the total amount of wood we processed.

Sauna

We upgraded a small external barn to a sauna, by insulating the walls with recuperated wood and building benches. We then introduced a big coal stove in a corner and fit it with a chimney connection

- Big old coal stove is fed with wood at the startup and with old oats (of which we have truckloads) during operation

- Temperature can reach about 70C

- Water can be poured on stones on top of the stove to get a wet sauna effect

Evaluation: 3 stars

It's cool to have it, but we are not using it very much as it needs some planning and some time to startup. If one day we manage to buy a second-hand projector we can convert this space to a winter cinema!

The luxurious benches of the sauna

The luxurious benches of the sauna

The 14kW ancient stove to power the sauna

The 14kW ancient stove to power the sauna

Compost of food scraps

- We built roofed compost boxes to avoid rain getting in.

- It is accessible to our chickens, which eat most of it. We placed a door on it to avoid chickens dragging everything out

- Good to pee on it in summer when it's too dry (Voilà an extra outdoor toilet...)

Evaluation: 4 stars

The design is robust. If we can fill it faster than the chicken empty it maybe we'll be able to fully evaluate its performance one day.

Compost boxes made of recuperated materials

Compost boxes made of recuperated materials

Hay/wood/materials management

Hand pushed cart to collect hay and other light stuff like branches

- We tried bike wheels but they collapsed under high loads of wood (yes, in practice we use it also for that sometimes and load 300kg of logs...) . We now built wooden wheels for it, but they are constantly risking to break again. Currently looking for motorcycle wheels of appropriate size to fit to it.

- Storage of hay: in the barn, preferably doing hayballs, rolling the hay into big pieces of fabric. *Could be nice to learn how to do a proper haystack*...

Our "3 stars" hand cart. We use it a lot. New wheels would bring it to 5 stars

Our "3 stars" hand cart. We use it a lot. New wheels would bring it to 5 stars

Irrigation system

- We recovered an old system of underground plastic pipes. With a cheap submerged pump we can then pump water from a small stream to a 2 cubic meter tank in the vegetable garden

- Recently we installed also a 1 cubic meter tank in the middle of the vegetable garden and connected it to a hose for ease of watering

Grass cutting

- Grass schythe and bush schythe: we are openly looking for someone who can train us on schythe sharpening and use.

- Some grasses are hard to cut manually, so at the moment we put back into use an old gasoline-powered grass cutter (to be used with moderation)

Wood cutting

- Branches and small logs: long scissors and axe, manual wood saw, 2-man saw

- Big logs: chainsaws (minimize them, but they are still essential), 2-man bowsaw, self-made stand for logs

Finishing of big logs:

- cutting them into chunks: tractor-driven circular saw

- splitting them: manual or electric wedge

- Generally logs are moved around as little as possible before final use to minimize work. they are stacked outside near to where the trees were cut. May need covering in winter

- Transport is done as much as possible manually (wheelbarrow / pushcart)

Pruning

- Pruning scissors, pruning saws, sharp blades

- Telescopic pruner (4 m long pole)

Land regeneration

One key way for us to regenerate land and to support new tree plantings is the addition of a lot of organic matter to the soil. In this context we acquired a professional-grade wood chipper. This is an example of fossil fuel powered and high tech solution that in my opinion still makes sense to adopt considering:

- The goal: regerate the land

- The efficiency of the machine: excellent. Can chip several cubic meters of branches in half an hour

- The alternative for getting rid of massive amounts o branches from pruning or wood-making operations: to burn everything on an open fire...which is the worse thing that can be done from an environmental standpoint.

I am now also researching on methods to upcycle small branches by putting them into trenches where they can get wet and decompose quicker, or by burying them underground. Once we build a big bread-oven maybe we can use some of them for heating it, as well.

Woodchips are the new gold

Woodchips are the new gold

Food handling and storage

- We handle large quantities of food (dumpster-dived or self-produced).

- We store fresh food on shelves in a dark and cool room + do periodic checks

Food storage in a cold back-corridor

Food storage in a cold back-corridor

Transport

- Bikes for everyone, including one folding bike for multi-mode transport

- Bike trailers: 2 trailers (belonging to the Ecotopia biketour)

One of the trailers we are "storing" :) for the Ecotopia biketour

One of the trailers we are "storing" :) for the Ecotopia biketour

Innovations in the pipeline:

- Fire-heated shower (drum refilled manually with hot water from the stove)

- Rainwater harvesting system (big drums connected to gutter pipes)

- Pee-harvesting system (for fertigation)

- Phytodepuration

- Bread oven

- Haybox

- Solar cooker

- Forge

- Wood splitting machine

- New bike trailer

- Hache Paille

End notes:

Innovation here is in constant evolution, so keep checking this blog for updates. Most of the technical solutions we are putting in place don't require "re-inventing the wheel" and have been used by humans for thousands (if not millions) of years.

Always beware of unproven and untested technology (like industrial pipelines, which haven't been and won't be around for long)!

You don't need to go "back to the stone age": going back to "iron age" is enough :)